Related Products

Rectangular bolted frame T SBF/BTB-X+X...X×N-N/M/W (back-to-back type)

Welding - rectangular

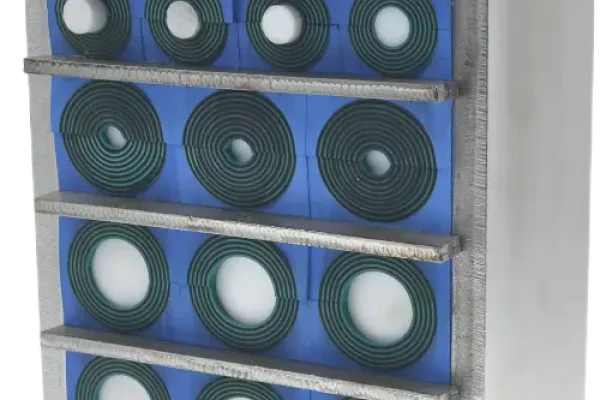

A back-to-back metal frame bolted to a metal or composite panel through a frame flange (N/M/W represents different flange widths, 40mm, 60mm, 100mm respectively), which can be equipped with fireproof sealing modules on the front and back sides of the frame to improve its protection capabilities.

Product Content

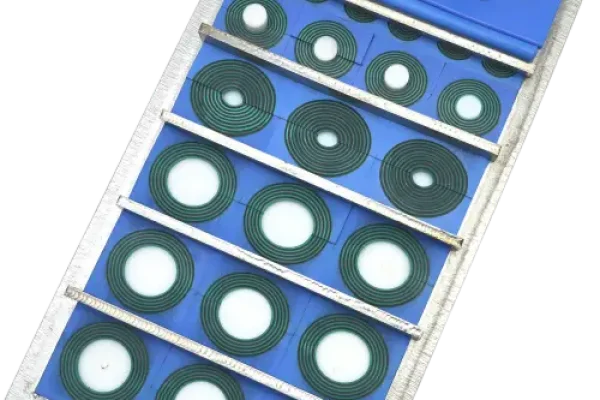

T SWS-X+X...X×N -AO Frame

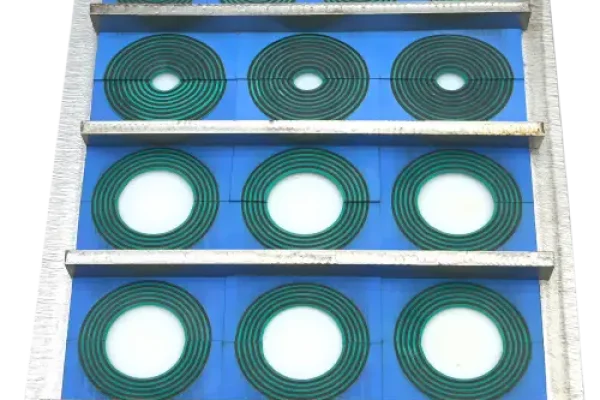

TSC-M Series Module

TSC-E Series blind plug module

Tensioner

SL-55 Grease

Interlayer

Product characteristics

| Fire Rate level | GB23864>1h、A-0、A-60 |

| Protection leve | IP68 |

| Watertightness | 0.3MPa |

| Airtightness | 0.3MPa |

| Lifespan | 30 years |

Customized product services

Cable/pipe sealing solutions that meet diverse needs can provide customized products and services.

Flexible application to different Dimensions of cables and pipes

EMC Solutions for electrical safety

For explosion protectionin hazardous areas solution

Suitable for armoured cable solution

be used in fresh water, chilledwater and waste water pipelines

be installed in wet conditions and running water

Non-welding solutions are available

Built-in spare capacity, easy to install Upgrade and renovate

Suitable for under ground application solution

Our Advantages

- 20 years of experience

- Source factory

- OEM/ODM customization

- Fast production and

- delivery

- Multiple patented

- technologies

- Comply with IATF16949

- ISO9001 standards

- Total factory area 50,000 m²

- Fireproof and waterproof

- EMI/EMP electromagnetic shielding

- Lifespan up to 30 years

Product Parameters

Sealing system – rectangular

Bolted – rectangular

T SBS/BTB-X+X…X×N-N/M/W is a sealing system bolted to a metal or composite panel through a frame flange. It consists of a rectangular back-to-back metal frame with flanges and rectangular sealing accessories. It can install modules on both the front and back sides of the frame. It is suitable for multiple dense cables and pipes of various specifications, and provides higher protection than the sealing system with modules installed on one side

Product model: T SBF/BTB-X+X…X×N-N/M/W (back-to-back type)

Product Description:

A back-to-back metal frame bolted to a metal or composite panel through a frame flange (N/M/W represents different flange widths, 40mm, 60mm, 100mm respectively), which can be equipped with fireproof sealing modules on the front and back sides of the frame to improve its protection capabilities. It is provided in different materials and contains a combination of single or multiple sealing cavity openings in the width and height directions

Material

304, 316L, Q345D (surface spray paint)

Can be bolted to metal or composite panels, and combined with other rectangular sealing accessories such as corresponding sealing pads to form a complete sealing system

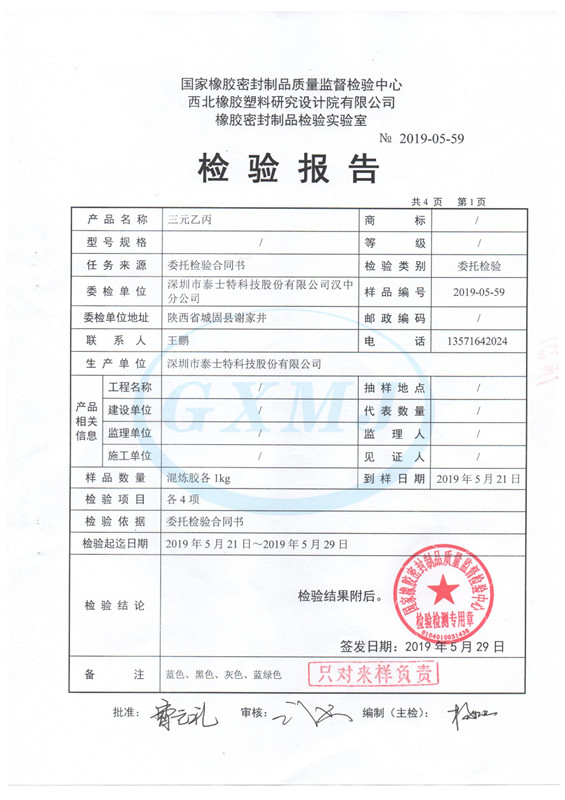

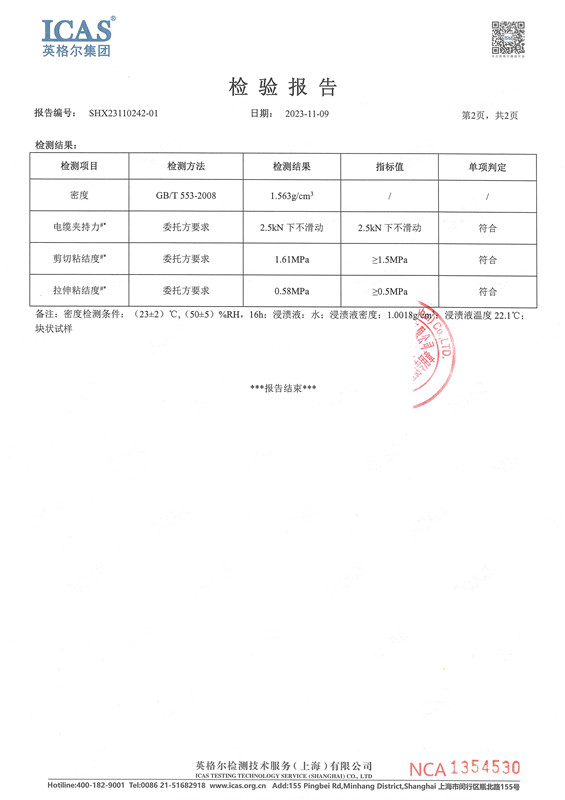

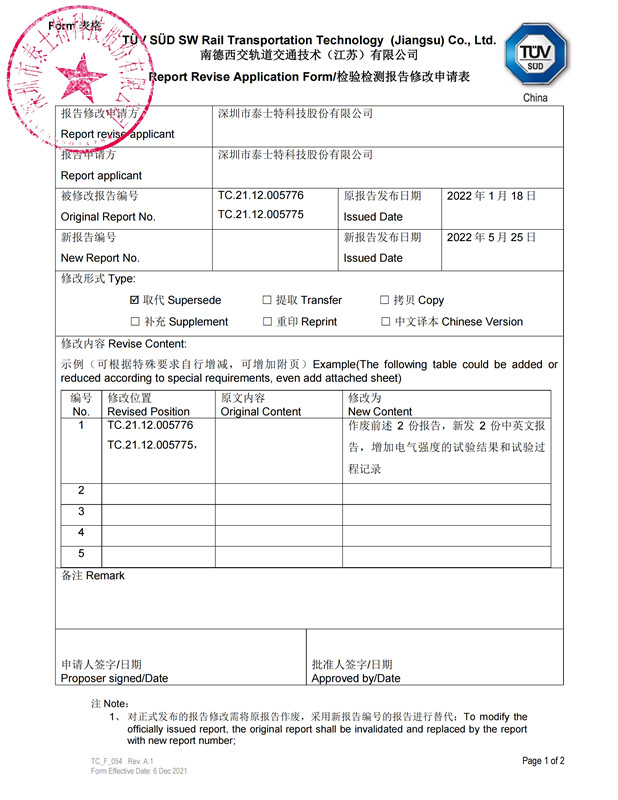

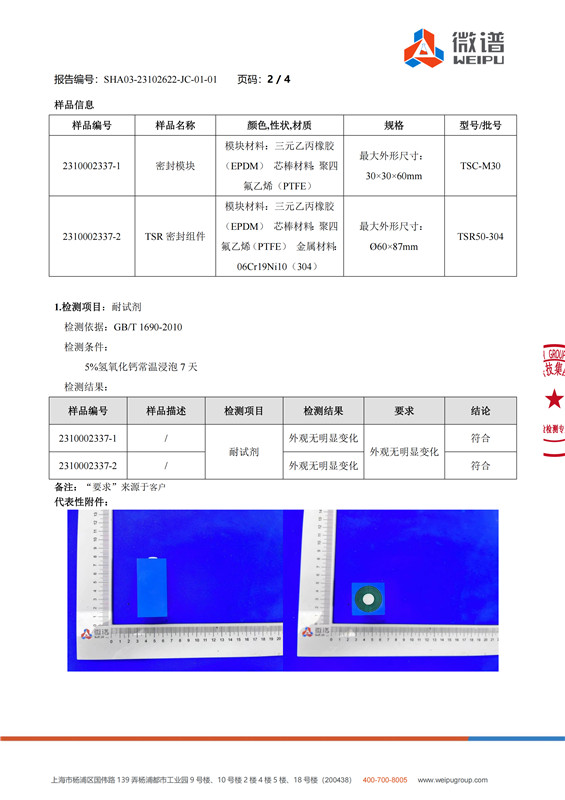

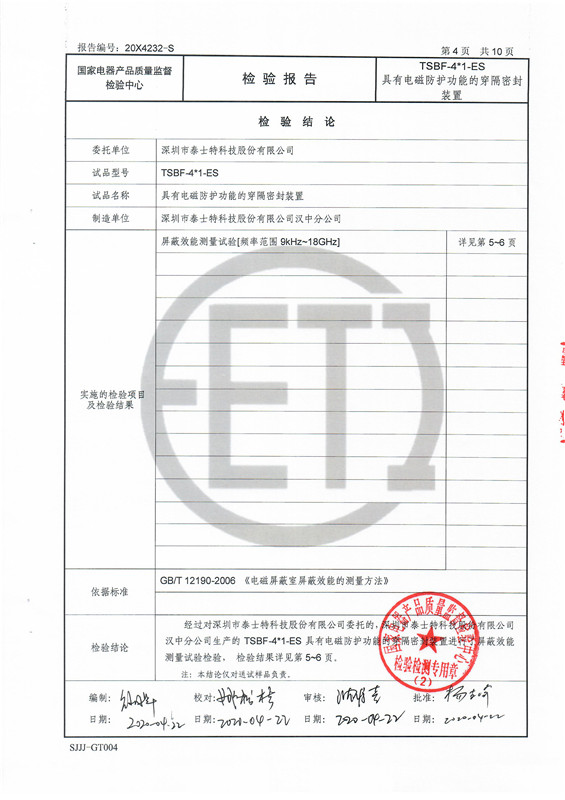

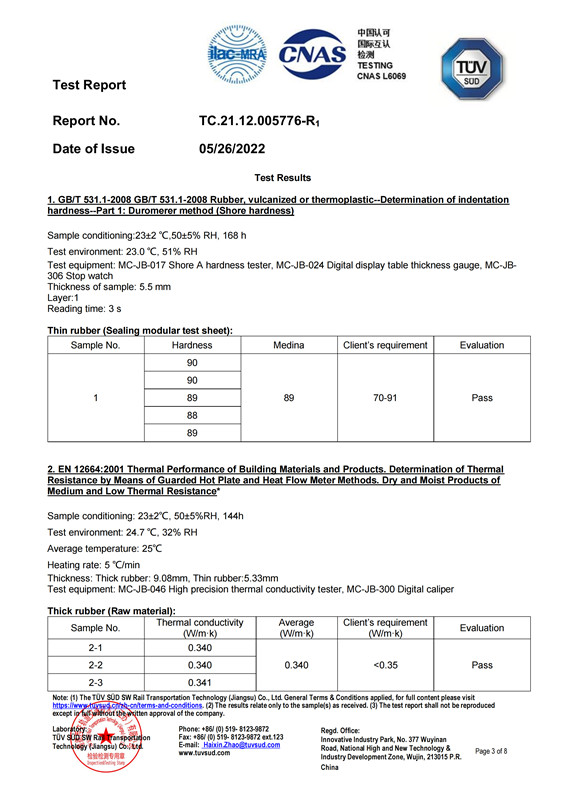

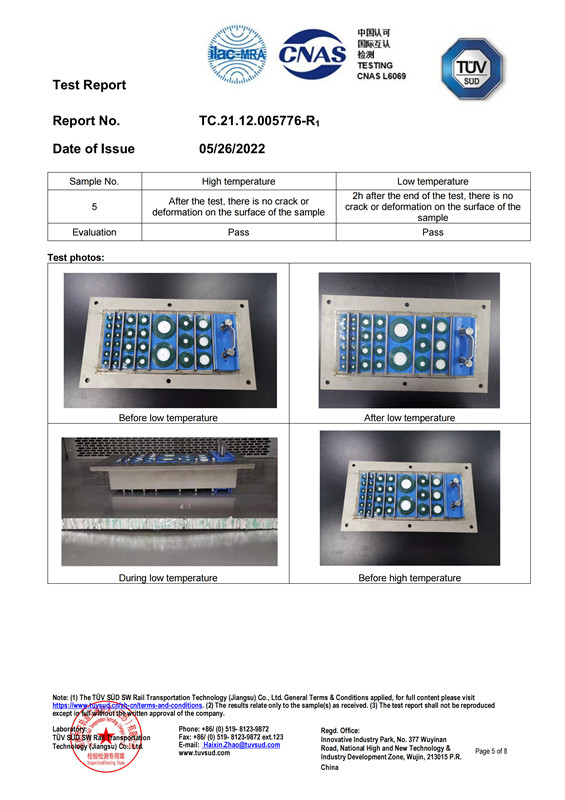

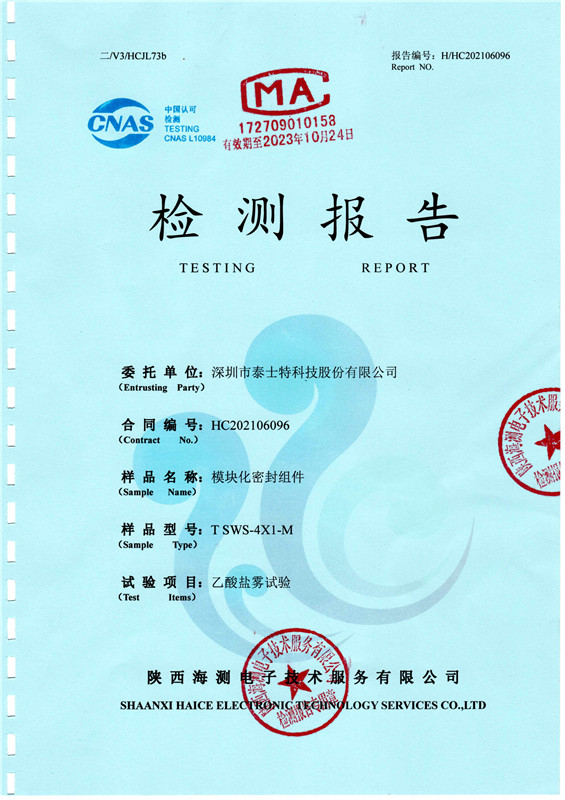

Related Certifications

TST SEAL have undergone rigorous testing and inspection: chemical analysis, aging test, vertical combustion test, acetic acid salt spray test, toxicity test, watertight and airtight performance test, electrical strength test, dust and vibration resistance test, corrosion resistance test, fire retardant performance test, noise resistance performance test, etc.