TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (12)

- rectangular seal (41)

- sealing modules (53)

- sealing solution (22)

- Tensioning Block (1)

Why is MTC cable penetration a "pain point" on offshore energy platforms?

Offshore oil and wind power platforms, as the “heart” of marine energy development, directly impact the continuity of energy supply and the safety of personnel. Cable penetration protection, as a “critical line of defense” for the platform’s electrical system, faces multiple severe challenges:

● Extreme Environment: The “triple corrosion” of high salt spray, strong ultraviolet radiation, and high humidity makes traditional seals prone to aging, cracking, and corrosion, leading to seal failure;

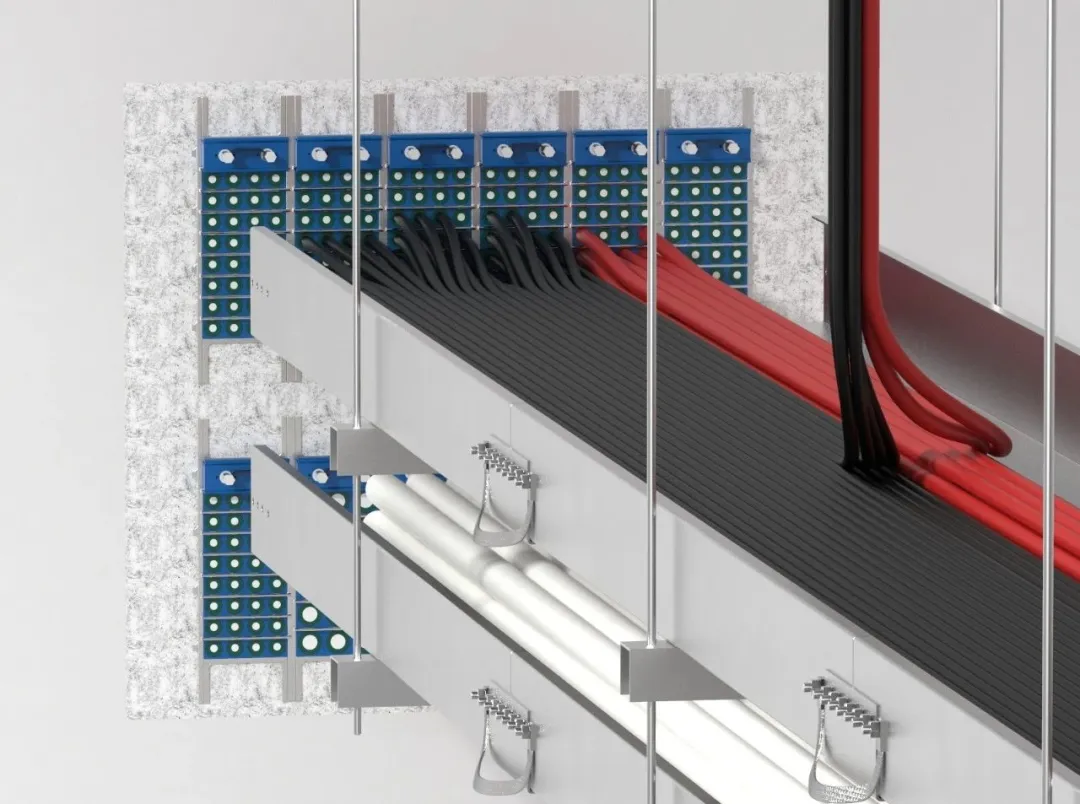

● Complex Specifications: Power, control, and communication cables vary greatly in diameter, and limited operating space makes traditional customized sealing solutions poorly adaptable, unable to meet the needs of penetrating mixed cable specifications;

● Vibration Interference: Continuous vibrations caused by wind, waves, and ocean currents can easily create gaps between seals and cables/holes, leading to protection failure;

● Difficult Maintenance: Traditional solutions require demolishing walls for later expansion or cable maintenance, resulting in high construction difficulty, high costs, and significant safety risks at sea. These pain points have long plagued the construction and operation of the platform. The TST seal MCT through-hole sealing system provides a sealing solution that combines high adaptability, strong protection, and ease of maintenance.

TST seal Modular Solution: Four Advantages to Solve the Problems

1. Full Size Adaptability: Say Goodbye to “Customization Hassles”

The core advantage lies in its peelable diameter variable technology, supporting flexible matching of different cable specifications. Whether it’s large-diameter power cables or small-diameter control and communication cables, precise sealing can be achieved through module adjustments, eliminating the need for custom-made seals for different cable specifications. During on-site construction, personnel can adjust the module size at any time according to the cable layout, easily achieving mixed through-hole sealing of multiple cable specifications, significantly improving construction flexibility and avoiding delays and increased costs due to changes in cable specifications.

2. Military-Grade Protection: Withstanding Extreme Environments

Utilizing military-grade composite protective materials, modified with a special formula, it possesses excellent resistance to salt spray, aging, and UV radiation:

● After 1000 hours of salt spray testing, the seals showed no corrosion or aging;

● Under strong UV radiation, it maintains elasticity and sealing performance for extended periods, extending its service life by more than 3 times compared to traditional products, significantly reducing platform maintenance frequency and costs.

3. Dynamic Seismic Resistance: Unfazed by Continuous Vibration

Targeting the vibration conditions of offshore platforms, the module structure design is optimized to create a seismically resistant sealing module. This module has passed the vibration and shock test of GB/T21563 standard, effectively absorbing continuous vibrations caused by wind, waves, and ocean currents, preventing the sealing gap from widening due to vibration, ensuring the integrity of the seal even in extreme vibration environments, and safeguarding the stable operation of the platform’s electrical system.

4. Efficient Maintenance: Reducing Safety Risks

Modular architecture makes installation and maintenance more convenient:

● Fast Installation: The “building block” design allows for installation with only simple tools, adapting to the confined working spaces of offshore platforms, increasing installation efficiency by over 60% compared to traditional solutions;

● Easy Maintenance: Redundant design with 40% expansion space allows for non-destructive cable addition or removal during future expansion or cable maintenance—no need to break through walls, only adjusting the corresponding modules is required, significantly reducing the difficulty and safety risks of high-altitude operations at sea.

Furthermore, the system also features IP68 watertightness and excellent airtightness, effectively preventing seawater and moisture intrusion, avoiding moisture-induced aging of the cable insulation layer, and further ensuring platform safety.

Currently, the TST seal modular cable penetration sealing system has been successfully applied in the construction and renovation projects of multiple offshore oil platforms and wind power platforms in the Bohai Sea and South China Sea. Tested in marine environments, its protective performance has remained consistently stable and reliable, making it the preferred solution for cable penetration sealing on offshore platforms.

From environmental adaptability to specification matching, from seismic design to efficient maintenance, TST seal’s modular solution uses cutting-edge technology to solve the challenges of cable routing at sea, providing a solid guarantee for marine energy development. In the future, TST seal will continue to innovate, helping offshore energy platforms operate more safely, efficiently, and sustainably.

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome |Ships within 24 hours (Email:alixich@tstcables.com)

TST SEAL has obtained certifications from DNV, RS, ABS, BV, RINA, CCS, CRCC, CCC, IOS, EN, ROHS & REACH, etc.