TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

TST seal penetration sealing system: an invisible guard protecting the safe operation of multiple fields

In the safety system of industrial infrastructure, cable and pipe penetration seals are like “vascular valves”, and their product performance is directly related to the reliability of industrial power transmission, signal control, and equipment operation and maintenance. Once threatened by extreme environments such as water, fire, insect pests, and electromagnetic interference, the equipment may be shut down at the least, or even cause catastrophic accidents at the worst.

As a national high-tech enterprise in the field of industrial penetration sealing technology in China, TST seal technology provides a new generation of modular sealing system solutions for penetration sealing of key parts and facilities in various fields around the world with its military-grade technical background. Today, let us unveil the mystery of this “invisible guard”!

Innovative breakthroughs from materials science to system engineering

TST seal, with more than 30 independent intellectual property rights and core patent technologies, is a leading brand leading the domestic innovation of variable diameter module sealing system technology, and a pioneer in the industrial wall-penetrating hydropower and rail transit industries. It serves well-known domestic companies such as the State Grid, the Three Gorges Group, and China Railway Construction, and has become the industry’s trusted choice with modular design and multiple protection performance.

1. Core material technology

Using aviation-grade EPDM substrate, nano-modification technology is used to achieve:

Electrical properties: volume resistivity>10¹⁵Ω·cm (ASTM D257)

Flame retardancy: Pass UL94 V-0, IEC 60332-1 and other standards

Environmental adaptability: -55℃~135℃ working conditions maintain flexibility (MIL-STD-810G verification)

2. Modular system design

Variation module based on topological optimization theory:

Supports mixed installation of Φ6mm~120mm cables

Sealing pressure can reach 0.5MPa (ISO 5208 standard)

Patented quick-install structure achieves:

Installation efficiency increased by 60%

Maintenance time reduced by 75%

3. Electromagnetic compatibility solution

Integrated EMI/RFI shielding design:

Shielding effectiveness ≥90dB (1GHz, IEEE 299 standard)

Passed MIL-STD-461G shipborne equipment test

Scenario King Full coverage from land to sea

The core advantage of TST seal sealing system: multi-scenario adaptive engineering protection system

In the field of industrial safety, the sealing system is not a simple “leak plugging” tool, but a key component related to the reliability of the overall system. The excellence of TST seal sealing system lies in its construction of a set of “material-structure-function” trinity adaptive protection system. Through modular architecture and intelligent design, it realizes accurate matching of all scenarios from land to sea, from normal temperature to extreme.

01 Infrastructure protection: building a solid safety line in all scenarios

Medical buildings: The positive pressure environment of the operating room and the airtight requirements of the disinfection area are all achieved by TST seal’s “fireproof + high airtightness” combination, adding another insurance for the safety of doctors and patients;

Data center: What is there to fear for a server running 7×24 hours? Fire, water, rodent infestation, electromagnetic interference – TST seal can handle them all, making the “data heart” beat more steadily;

Railway transportation: high-speed rail is speeding, subways are shuttling, and the signal system cannot have any mistakes! The TST seal sealing system supports the rapid laying of cables of multiple specifications, and there is no need to open new holes for later capacity expansion, which saves money and worry;

Airport: From radar antennas to navigation systems, from underground trenches to terminal power distribution, TST seal uses EMC electromagnetic compatibility design to ensure that the aviation signal chain is foolproof.

02 Power breakthrough: Safety valves for energy arteries

Nuclear power: Safety protection requirements are relatively strict. The TST seal sealing system can simultaneously meet the triple protection of fire protection (3-hour fire resistance limit), waterproof (LOCA accident conditions), and radiation protection (10⁶Gy irradiation dose). The penetration can withstand 1.2MPa instantaneous pressure shock (in compliance with RCC-E standards). Traditional sealing structures require the demolition of concrete walls for equipment upgrades, and the manual operation time is limited in radiation environments. TST seal sealing products solve industry construction problems.

Wind power: Offshore wind turbines face salt spray, strong winds, and lightning all year round. The TST seal sealing system uses a lightweight design to reduce the tower load and withstand the bombardment of extreme weather;

Hydropower: The vibration, water pressure, and electromagnetic environment inside the dam can be called a “devil’s test”. TST seal uses a vibration reduction module + impact resistance design to protect every degree of energy in hydropower generation.

03 Industrial Intelligent Manufacturing: A Bodyguard for Precision Equipment

Rolling Stock: Meets the highest fire protection level HL3 of EN 45545-2, 120 minutes of flame retardant time + low smoke density and toxicity, creating a mobile safety cabin for high-speed rail and subway;

Mechanical Equipment: The cable pipes of cranes and robots are often faced with frequent vibration and oil erosion. The TST seal sealing system uses oil-resistant modified materials + fastening design to extend the life of the equipment by 30%;

Smart Factory: Pre-install the openable sealing module in advance, and there is no need to stop the work and transform the newly added cables in the later stage, truly realizing “layout today, upgrade tomorrow”.

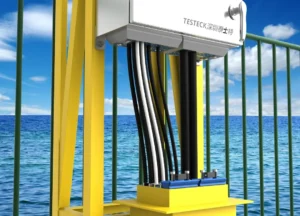

04 Maritime Legend: Security Code for 10,000-ton Ships

Transport ships/cargo ships: The most feared thing when sailing at sea is watertight failure and fire spread. The TST seal sealing system has passed strict certifications such as IMO, allowing ships to remain “indestructible” in stormy waves;

Cruise ships/passenger ships: Lightweight design reduces hull weight, non-welding installation simplifies construction, and even upgrades to “green equipment” such as ballast water treatment systems can be easily adapted;

Navy ships: Anti-explosion shock, anti-electromagnetic pulse, and resistant to seawater corrosion, TST seal creates “three-proof armor” for ships to help improve their survivability in maritime operations.

TST seal has successfully passed the formal approval and factory approval of Russian Classification Society (RS) and China Classification Society (CCS). TST seal MCT products are used in modern floating power generation ships, LNG carriers and other special ships jointly built by China and Russia. “Multi-scenario cable and pipeline sealing”, no secondary transformation is required, which has laid a solid foundation for its entry into the global ship and marine engineering field.

05 Marine Engineering: A safety barrier for deep-sea secrets

Drilling platform: TST seal EMC collaborative shielding solution overcomes the triple extreme working conditions of ultra-high pressure, strong corrosion, and flammable and explosive deep-sea drilling platforms. Through innovatively developed composite shielding structure design and corrosion-resistant alloy materials, the electromagnetic interference attenuation rate is successfully increased to 98.5%, and the protection level reaches IP68 standard. With the intelligent monitoring system, 24-hour environmental safety warning is achieved, which significantly improves the safety level and operation efficiency of deep-sea oil and gas exploitation. (Passed ISO 21457 anti-corrosion certification and ATEX explosion-proof certification)

Offshore booster station: Modular standard parts are quickly installed to solve the fireproof sealing problem of offshore wind power cable penetration, which is “blue energy” Development escort.

06 Energy and Chemical Industry: Safety barrier for dangerous scenes

Petrochemical Industry: Variable diameter modules are suitable for pipelines and cables of different sizes, easily coping with complex working conditions of refineries and oil storage depots, and keeping flammable and explosive areas away from safety hazards;

Mining Industry: The risks of dust, moisture, and gas leakage in mines are resolved one by one by the TST seal sealing system, creating a safer working environment for miners.

3 reasons to choose TST seal

1. Reduce costs and increase efficiency

The modular design reduces installation time by 50%, and redundant reservations avoid repeated openings in the later stage, and the cost of the whole life cycle is reduced by 40%;

2. Certification support

CCCF UL, NEMA, IP68, fire protection test, etc. 80+ international and domestic certifications, adapted to strict global standards;

3. Full escort

From the initial solution design to installation training and after-sales inspection, TST seal provides “nanny-level” services to make customers worry-free throughout the process.

With excellent product performance and reliable quality assurance, TST Seal has successfully provided more than 3,000 sets of domestic cable pipe penetration and sealing solutions for more than 1,000 listed groups, state-owned enterprises, and central enterprises around the world, including Wison Group, Mingyang Electric, State Grid, and China Southern Power Grid.

Under the wave of “dual carbon” goals and intelligent manufacturing, the importance of industrial safety is increasing day by day. TST seal technology has always taken “technological innovation” as its engine, continued to deepen the field of penetration and sealing technology, and used “hard-core products” to build a solid safety foundation for various industries.

Whether you are an infrastructure maniac, an energy giant, a manufacturing pioneer, or a maritime elite, the TST seal cable pipe sealing system is a safety partner you can’t miss!

If you have a need for a sealing module, please send an email to TST seal’s official customer service, contact us, and get exclusive safety solutions, so that every penetration becomes a safe starting point!