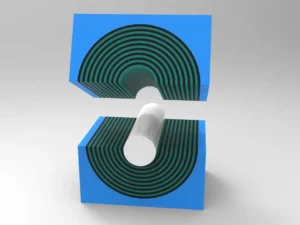

TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

TST seal empowers the 3.0 era of penetration seals. New modular sealing systems usher in major opportunities

Driven by the global energy revolution and the national “14th Five-Year Plan” renewable energy development plan, China’s new energy industry is reshaping the world’s energy map with a prairie fire. According to data from the National Bureau of Statistics, new energy has become a new growth pole for the domestic economy. However, as the new power system has achieved substantial results, the cable and pipeline sealing penetration system has become an issue that needs urgent attention in responding to the multiple scenario requirements of the complex working conditions of the new energy industry. Traditional sealing technology is not flexible enough and has high maintenance costs, making it difficult to adapt to the diversified needs of the new energy industry. At the same time, the complex and changing international situation has limited the supply of imported cable and pipeline sealing products, and they are facing the risk of supply interruption and after-sales service at any time. In such an industry dilemma, Made in China-TST seal “peelable variable diameter” modular sealing system stands out in the opportunities of the times with “dynamic adaptability, sealing continuity, maintenance efficiency and stable delivery capability”, and has become an excellent supplier of domestic substitution!

01 Industry support

Twenty years of accumulation has created a foundation for global trust

Since its establishment in 2003, TST seal has always focused on the technological innovation of industrial penetration modular sealing systems. Its business network covers the world, providing more than 3,000 sets of domestic cable pipe penetration sealing solutions for the State Grid, China Southern Power Grid, Huadian Group, Datang Group, Three Gorges Group, Dadu River Group in the energy field, and China Railway Construction and high-speed rail, subway and other 1,000+ listed groups, state-owned enterprises, and central enterprises in the rail transportation field. After more than 20 years of rigorous working condition verification, TST seal has forged an international standard quality control system with military quality, providing rich experience support for the new energy industry.

02 Dynamic adaptation

Cracking the “thousand-faced needs” of new energy scenarios

TST seal’s “peelable variable diameter” modular sealing system can be called the “all-round adapter” of the new energy industry. The system has high adaptability and can accurately and flexibly match the diverse needs of the new energy industry. Whether in wind farms, solar photovoltaic power stations, or in new energy vehicle charging piles, energy storage power stations and other scenarios, TST seal’s sealing system can play its unique advantages – modular combination to achieve dynamic adaptation of pipe diameters, with EPDM rubber elastomer materials, to maintain reliable sealing stability under complex working conditions. This “building block” design increases the efficiency of on-site adjustment by 60%, successfully solving the industry pain point of “one size fits all” of traditional sealing solutions.

03 Technical breakthroughs

Dual value of cost and efficiency balance

Facing the core demands of cost reduction and efficiency increase in the new energy industry, TST seal’s military-level R&D team continuously optimizes the structure and material properties of the sealing system, solving the core pain points of traditional solutions in adaptability, durability and maintainability: variable diameters efficiently adapt to different specifications of pipeline sizes, combined structures do not require pipeline removal for later maintenance, one-time investment, 30 years of use, and full-cycle convenience. This dual optimization of cost and efficiency allows TST seal’s products to stand out in the market competition and create higher value for customers.

04Stable delivery

The era of domestic supply chain

Against the backdrop of the global tariff war, the supply and after-sales of imported products are full of uncertainty. Once a supply interruption occurs, it will bring huge losses to new energy companies, and after-sales interruption will also bring huge maintenance pressure to the company, and even affect the progress of the entire project. TST seal, with its perfect supply chain system and strong production capacity, has stable and fast delivery capabilities and strict management processes to ensure that every link can operate efficiently and deliver products to customers on time, according to quality and quantity. At the same time, it provides personalized customization of products, timely response 7*24 hours, 1 to 1 product guidance, safety risk assessment, on-site installation guidance, and full-cycle after-sales service. This stable delivery capability and down-to-earth service make TST seal a safe choice for new energy companies and a pride of domestic substitution.

05Scenario empowerment

Deep integration into the new energy ecological chain

Photovoltaic field

In large-scale photovoltaic power stations in the northwest, sand and dust invasion has always been a problem that plagues the stable operation of power stations. A large amount of sand and dust enters the cable and pipeline system, which will cause frequent inverter failures. With its unique structural design and high-performance sealing materials, the TST seal peelable sealing system is like a solid barrier that keeps sand and dust out.

Offshore wind power

Offshore wind power projects have long been facing harsh environments such as strong winds and salt spray, and have extremely high requirements for the sealing and seismic resistance of cable connectors. TST seal’s seismic-resistant sealing module, developed for the special working conditions of offshore wind power, uses high-strength, corrosion-resistant materials, combined with precise seismic-resistant structural design, to ensure the continuous and stable power generation of offshore wind power equipment.

Electrochemical energy storage

In large-scale energy storage power stations, the fire and explosion resistance of energy storage cabinets is crucial. The TST seal fireproof sealing solution uses materials with excellent flame retardant properties, and through scientific sealing structure design, it has successfully passed the strict fire test standards, greatly improving the safety and reliability of the energy storage system.

Standing at the forefront of the energy revolution, TST seal is breaking the technical monopoly of overseas brands in the field of high-end sealing with the dual innovation of “technology + manufacturing”. Its value lies not only in providing domestic alternatives, but also in building an independent and controllable supply chain ecosystem for China’s new energy industry. TST seal is not a follower of import substitution, but a leader in redefining sealing technology. This confidence comes from twenty years of focus and a firm belief in the future of China’s smart manufacturing. In the global race for carbon neutrality, such stories will continue to unfold.