TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

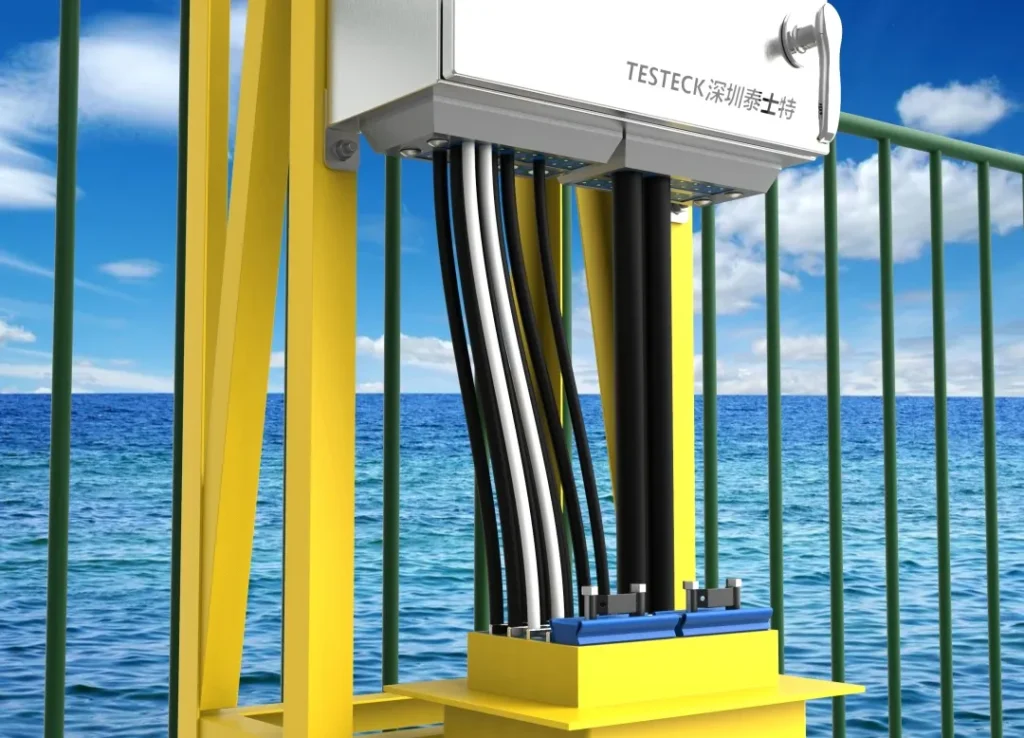

Offshore oil sealing and fire protection: the life and death protection of cabinet and cabinet sealing modules

Across the vast ocean, far from shore, offshore oil platforms stand like isolated islands of steel, battered by wind, waves, and corrosion. Every control cabinet and electrical box is a core node in the platform’s “nervous system.” The key to their survival in the face of salt spray, high pressure, vibration, and extreme temperature swings lies in a seemingly small yet crucial component: the TST SEAL sealing module. It’s not only the “first line of defense” against dust and water, but also the “lifeline” that ensures safe oil and gas production and prevents catastrophic accidents.

The “ultimate battlefield” of salt spray corrosion: From “rust trap” to “chemical shield”

The offshore environment can be described as “hell mode” for industrial equipment: chloride ion concentrations in the air can reach over 10 times that of land, causing metal components to rust through within months. Traditional rubber seals rapidly age and crack under salt spray, allowing moisture to intrude, causing electrical shorts and control system failures. Today, ethylene propylene diene monomer (EPDM) and fluorocarbon rubber (FKM) are the mainstream sealing materials. EPDM offers excellent weather resistance, operating stably in temperatures ranging from -50°C to 150°C, and exhibits exceptional resistance to UV rays and ozone. FKM, on the other hand, specializes in highly corrosive environments, offering exceptional resistance to crude oil, acid gases, and seawater. Sealing companies like TST SEAL utilize a double-layer EPDM seal and a 316L stainless steel gland structure, ensuring enclosures meet IP68 protection standards—proof of entry after immersion in 1.5 meters of water for 48 hours.

A real-world case study: On the “Deep Sea No. 1” platform in the South China Sea, a control cabinet experienced a seal failure, resulting in a short circuit in a PLC module and an emergency gas well shutdown, resulting in losses exceeding 10 million yuan. Subsequently, the system was fully upgraded to the TST SEAL FKM sealing system, and within three years, no moisture-related electrical failures have occurred.

The “Life and Death Line” of Explosion-Proof Safety: The Hard-Core Protection of Ex-Certified Sealing Systems

Offshore platforms have numerous confined spaces and a high risk of natural gas leaks. Once an electrical spark ignites, the consequences can be devastating. Therefore, all electrical enclosures must comply with explosion-proof standards (such as IECEx and ATEX), and sealing modules are crucial for explosion-proof performance.

The explosion-proof junction box sealing system utilizes a metal thread compression and graphite-filled sealing ring design to ensure gap-free cable entry. Even if an internal explosion occurs, flames will not escape along the cables. Furthermore, the sealing structure provides grounding (BG) and shielding (SE) functions, effectively dissipating static electricity, shielding electromagnetic interference, and preventing signal distortion.

Technical Highlight: The TST SEAL sealing module integrates “PE/SE/BG three-in-one” technology. During testing on an offshore platform in Hebei, it successfully blocked a 0.8 MPa explosion shock wave, becoming a “safety wall” in high-risk petrochemical areas.

“Flexible Buffering” of Vibration and Displacement: TST SEAL’s Intelligent Dynamic Sealing

Offshore platforms are constantly impacted by waves, with equipment vibration frequencies reaching 5-50Hz. Traditional rigid seals are highly susceptible to fatigue failure. Therefore, elastic pre-compression sealing technology has emerged.

This technology pre-compresses an EPDM sealing strip within the sealing groove, creating an “adaptive buffer layer.” When the enclosure experiences slight displacement due to vibration, the strip dynamically rebounds, maintaining a tight fit. Furthermore, stainless steel bellows compensators are used at the joints of large cabinets to absorb axial and angular displacement and prevent flange loosening.

Data comparison: Cabinets using TST SEAL’s dynamic sealing system have seen an 80% reduction in vibration-induced seal failure rates, and the average maintenance interval has been extended from six months to over three years.

Intelligent Sensing: From “Passive Protection” to “Active Warning”

The future has arrived. TST SEAL’s next-generation intelligent sealing module is quietly making its debut. On a FPSO (Floating Production Storage and Offloading) vessel in the East China Sea, some key control cabinets are equipped with embedded sensor seals that monitor internal humidity, temperature, and pressure changes in real time.

If a rise in humidity or a drop in seal pressure is detected, the system immediately transmits an early warning to the central control room via a wireless module. This allows operations and maintenance personnel to intervene before a failure occurs, achieving “predictive maintenance.” It is estimated that this technology can reduce unplanned downtime by 40% and annual operation and maintenance costs by 25%.

An “all-round warrior” for extreme environments: TST SEAL’s integrated sealing module solution

Faced with complex operating conditions, a single seal is no longer sufficient. The industry is shifting towards integrated sealing systems. For example, TST SEAL’s new flange seal integrates:

Corrosion-resistant fastening ring (316L stainless steel)

Adjustable shaft clamping structure

Double-layer EPDM sealing strip

Electromagnetic shielding layer

Ground terminal

This “five-in-one” solution not only protects against dust and water, but also against rodents, electromagnetic interference, and mechanical shock, becoming a “comprehensive shield” for offshore platform electrical systems.

Ten thousand meters above the surface, on a drilling rig, in the gloom of a control room, sealing modules silently endure the test of wind, waves, salt spray, and time. Though inconspicuous, they are the lifeline of offshore oil safety. Behind every precise valve control and every kilowatt-hour of stable electricity output lies the silent protection of sealing technology.

As my country accelerates deep-sea oil and gas development, from “combustible ice” pilot production to ultra-deepwater projects in the South China Sea, the requirements for sealing technology will become even more stringent. The innovative breakthroughs of Chinese companies are making “Made in China “TST SEAL sealing modules an indispensable “invisible backbone” of the global marine energy landscape.

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome (Email:alixich@tstcables.com)