TST Seal :

Fireproof

Cable fixinAg

Watertight

Airtight

Dustproof

Noise reduction

Vibration reduction

Pressure resistance

Corrosion resistance

EMI/EMP

Pest & rodent resistance

TST SEAL INDUSTRY APPLICATION

Sealing module solutions for the marine engineering industry

Most of the cables and pipes in the industrial field are sealed and plugged by traditional refractory mud, refractory glue, metal glands, etc. They are very troublesome and cumbersome when facing the installation and removal of cables, and the sealing and fire resistance levels do not meet the requirements, and regular maintenance is required; these problems have always plagued the protective plugging in the industrial field and brought great safety hazards.

TST SEAL can provide non-destructive disassembly and assembly, variable diameter, low smoke halogen-free flame retardant, fire resistant for 2h, IP68 protection, and anti-electromagnetic interference, lightning shock and surge protection. The combination of pipe and sealing module components can be used in any combination.

TST SEAL cable/pipe penetration sealing system (MCT) is used in the field of maritime and marine engineering, drilling platforms, offshore booster stations, etc. It can seal cables and pipes conveniently and effectively, can prevent fire, and can also resist erosion by multiple risks such as water, gas and rodents.

- Sealing module Marine engineering scenario introduction

In the marine engineering industry, such as drilling platforms and offshore booster stations, cable and pipe sealing modules are used to ensure the safety and reliability of electrical equipment, control systems, and data transmission lines. These facilities are usually located in harsh marine environments and face challenges such as high humidity, salt spray corrosion, and extreme weather conditions.

- Market pain points

Corrosion problem: Seawater and salt spray are extremely corrosive to metal parts.

Waterproof demand: Prevent seawater from invading cable channels and causing short circuits or other electrical failures.

Temperature change: The temperature in the marine environment fluctuates greatly, requiring sealing materials to adapt to a wide operating temperature range.

Mechanical stress: Marine engineering facilities are often impacted by wind and waves and need to have good vibration resistance.

Fire risk: In the event of a fire, cables and pipes that are not properly sealed may become channels for the spread of fire.

Electromagnetic interference (EMI): For sensitive equipment in data centers and hospitals, external electromagnetic interference must be prevented from affecting normal operation.

Environmental adaptability: Different climatic conditions require sealing materials to have good weather resistance.

Subsequent maintenance is difficult: Traditional sealing methods often cannot meet the needs of future upgrades and renovations.

- Advantages of TST SEAL sealing module solutions:

Product features Using TST SEAL cable duct sealing system can prevent multiple risks:

Fire and smoke prevention

Prevent the spread of fire and smoke.

Waterproof and corrosion-resistant

Keep the device safe and dry.

Prevent moisture, water seepage, flooding and corrosion.

Pests

Keep snakes, insects and rodents out.

Ensure cable fixation and stress relief.

Gas and air

Ensure the integrity of the seal and prevent the influence of air and air pressure.

Electromagnetic threats

Resist the effects of EMI, EMP and lightning strikes.

High and low temperature resistance, tensile resistance and radiation protection

Temperature challenges

Cope with hot, cold and changing temperature environments

With super UV resistance

Explosion

Resist vibration and explosion loads, as well as the risk of explosion.

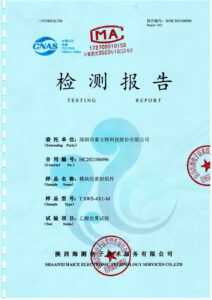

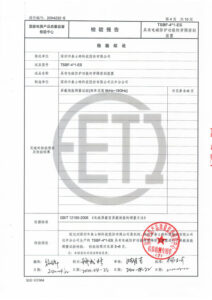

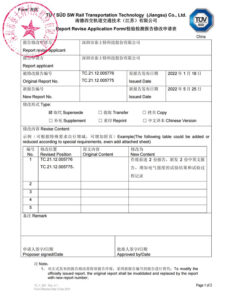

- The certification standards that the TST SEAL sealing module system complies with include but are not limited to:

UL (Underwriters Laboratories)

IEC (International Electrotechnical Commission)

EN (European Norms), EN45545-2, EN45545-3

GB (Chinese National Standards), GB23864 (2H)

CCCF certification (GB23864)

5.Some patented technologies of TST SEAL

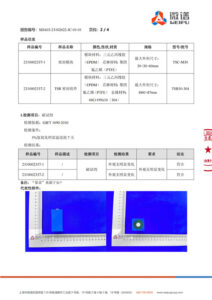

TST SEAL have undergone rigorous testing and inspection: chemical analysis, aging test, vertical combustion test, acetic acid salt spray test, toxicity test, watertight and airtight performance test, electrical strength test, dust and vibration resistance test, corrosion resistance test, fire retardant performance test, noise resistance performance test, etc.

- Sealing module selection guide Select the appropriate sealing module according to the marine engineering application scenario, and consider the following factors:

Specific requirements of the working environment (such as depth, salinity, etc.)

Required protection level (IP level)

Operating temperature range

Whether electromagnetic shielding is required

Installation space restrictions

Cost-effectiveness ratio

- Sealing module product features and product selection recommendations

The sealing modules provided by TST SEAL have the following characteristics:

Use non-toxic and halogen-free EPDM rubber as the base material

Support peelable variable diameter technology for easy size adjustment

Provide excellent electromagnetic shielding performance

Modular design, easy to expand and maintain

Recommended products

8.TST SEAL sealing module technical test

Salt spray test

Temperature cycle test

Vibration test

Pressure test

All TST SEAL sealing module products are strictly tested to ensure that they meet the specified fire, water and dust resistance levels and can maintain stable performance under extreme conditions.

- Sealing module installation and commissioning

During installation, the instruction manual provided by the sealing module manufacturer TST SEAL should be followed to ensure that each step is performed correctly. A pressure test is required after the initial installation to verify the sealing effect.

- Infrastructure industry sealing module solution case

TST SEAL penetration sealing components are widely used in various industries such as ocean, shipbuilding, military industry, medical, infrastructure, rail transportation, construction, electricity, oil and gas, and chemicals.

For example, in the infrastructure cable wall transformation project of the Emerson Network Power (Xi’an) offshore power tower sealing project, TST SEAL’s modular cable duct sealing system was used, which successfully solved the problem that traditional sealing methods could not meet the needs due to frequent upgrades, while improving overall safety and reliability. Through the above solution, customized sealing module solutions can be provided for different types of infrastructure projects to ensure their long-term safe operation.

More TST SEAL marine engineering sealing module application cases:

Bohai Oilfield CEPI Platform

State Power Investment Jieyang Shenquan 1 400MW Offshore Wind Farm Project

Emerson Network Power (Xi’an) Offshore Power Tower Sealing Project

Zhangpu Liuao Phase II Offshore Substation Fireproof Sealing Module Procurement Project

Three Gorges Yangjiang Shaba Offshore Substation Project

Huadian Yuhuan No. 1 Offshore Wind Farm Project