TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (12)

- rectangular seal (41)

- sealing modules (53)

- sealing solution (22)

- Tensioning Block (1)

How does the TST SEAL Peelable Rubber Block Penetration Sealing System achieve waterproof and fireproof performance?

The TST SEAL peelable rubber block, as the core component of the penetration sealing system, does not inherently possess fireproof and watertight properties. These properties are achieved through a three-pronged approach: material science, structural design, and system integration. Below, TST SEAL Nico clearly explains, from principle to practice, how it achieves “fire containment and water tightness.”

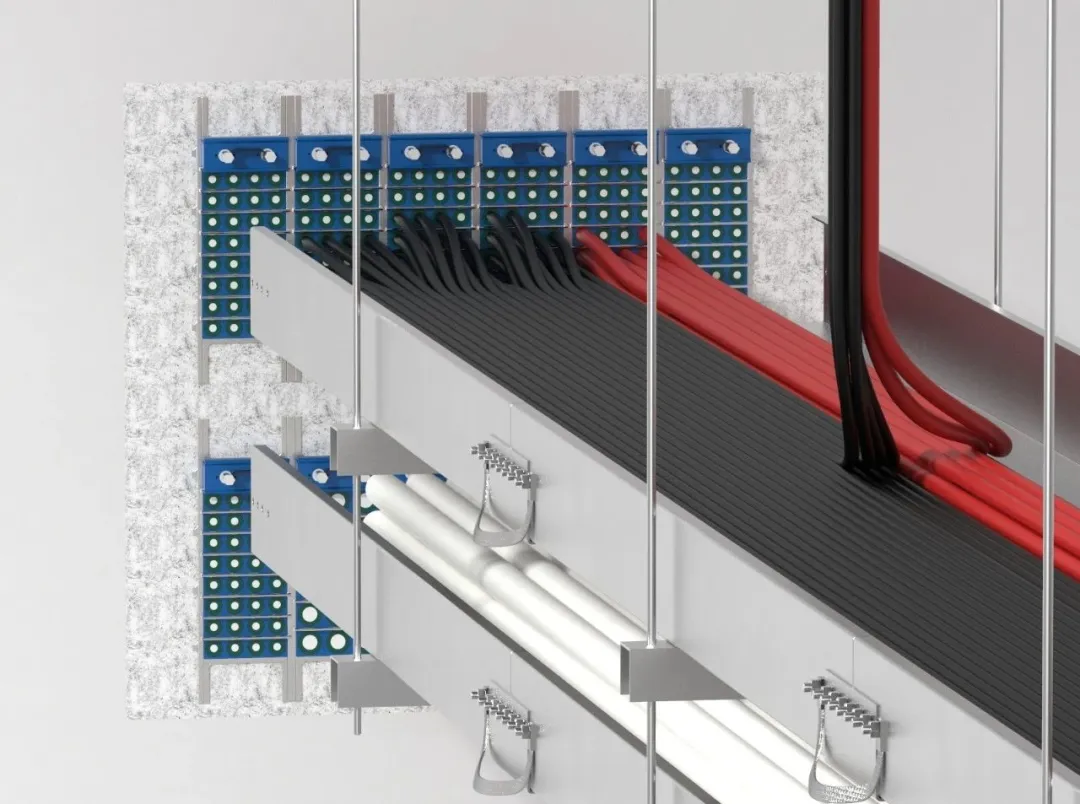

- Watertight Performance: TST SEAL sealing modules achieve IP68 through “dynamic fitting + elastic compression”

✅ 1. Intrinsic Material Sealing

The main body uses high-elastic EPDM or silicone rubber, with a Shore hardness typically of 55–70A, making it both soft and pressure-resistant;

The rubber itself is dense and non-porous, preventing water molecules from penetrating (volume resistivity >10¹⁴ Ω·cm).

✅ 2. Maintains a complete sealing lip after peeling

The peelable module is not “cut,” but rather torn along a preset weak line, with the inner edge retaining a continuous sealing lip;

When the cable is inserted, the rubber rebounds radially under the frame’s clamping force, tightly enveloping the cable sheath, forming an “O-ring effect.”

✅ 3. System-level compression sealing

The TST SEAL sealing module is installed in a metal frame (such as 316L stainless steel), and axial pressure is applied through bolts (usually ≥15 kN);

The pressure causes permanent deformation + elastic recovery of the rubber, maintaining contact stress >0.5 MPa even with slight cable vibration, ensuring:

IP68 protection (1.5 meters water depth, continuous 72 hours without leakage);

0.5 MPa hydrostatic pressure test passed (equivalent to 50 meters water depth), meeting classification society requirements.

📌 Test Case: In DNV certification testing, the TST SEAL TST-MCB module with a Φ50mm cable penetration withstood 0.6MPa water pressure for 30 minutes without any leakage.

- Fireproof Performance: Achieving A-60 through “intumescent flame retardancy + structural integrity”

Fire protection is not about “not burning,” but about preventing the penetration of flames, smoke, and high temperatures within a specified time. TST SEAL peelable modules achieve their performance through the following methods:

✅ 1. Flame-retardant material formulation

EPDM base material is added with halogen-free flame retardants (such as aluminum hydroxide and magnesium hydroxide), which decompose upon contact with fire, absorbing heat and releasing water vapor to dilute oxygen;

Oxygen index (LOI) ≥32%, reaching UL94 V-0 or IEC 60332-1 flame retardant rating;

Low smoke and non-toxic during combustion (compliant with IEC 60754-2, halogen acid gas <5mg/g).

✅ 2. High-temperature expansion sealing mechanism

In the A-60 fire test (1010℃ flame, lasting 2 hours), the rubber softens when heated but does not melt or drip;

At the same time, some high-end products incorporate expandable graphite or ceramic fillers into the rubber:

When the temperature >300℃, the material begins to carbonize and expand, increasing in volume by 10–15%;

A dense carbon layer is formed, blocking gaps and isolating oxygen and heat transfer.

✅ 3. Synergistic fire protection with metal frames

The module must be used in conjunction with an A-60 certified metal penetration frame;

The frame provides structural support to prevent wall deformation at high temperatures, which could lead to sealing failure;

The entire system has passed tests according to standards such as IMO FTP Code / EN 1366-3 / GB/T 9978, and obtained A-60, A-30, or H-120 fire rating certificates.

📌 Case study: A naval vessel project used the TST-MCB + 316L frame system. In the China Classification Society (CCS) A-60 test, the temperature rise on the back of the fire-exposed side was <140℃, with no flame penetration, successfully passing the 2-hour test.

III. Key Premise: Cannot operate in isolation, must be a system integration

⚠️ Special Note:

The TST SEAL peelable rubber block itself is not a fireproof/watertight unit, but part of a penetration sealing system. Its performance depends on:

Correct selection (matching cable outer diameter within ±2mm);

Standardized installation (bolt torque meets requirements, no bias);

Used in conjunction with certified frames, partitions, and fire-resistant fillers. If used alone or installed improperly, even the best materials will fail.

The TST SEAL variable-diameter sealing module is not a “magic rubber,” but rather a product of “precision engineering.”

The reason TST SEAL’s peelable rubber module can withstand both high-pressure seawater and scorching flames at thousands of degrees Celsius is not due to any mystical properties, but rather the perfect combination of material chemistry, mechanical design, and systems engineering. It acts like a “flexible guardian”—gently enveloping cables in normal times, and transforming into a fireproof barrier in critical situations.

It is for this reason that TST SEAL has earned trust in high-safety fields such as global shipping, offshore engineering, rail transit, and energy storage, becoming the “gold standard” for modern penetration sealing.

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome |Ships within 24 hours (Email:alixich@tstcables.com)

TST SEAL has obtained certifications from DNV, RS, ABS, BV, RINA, CCS, CRCC, CCC, IOS, EN, ROHS & REACH, etc.