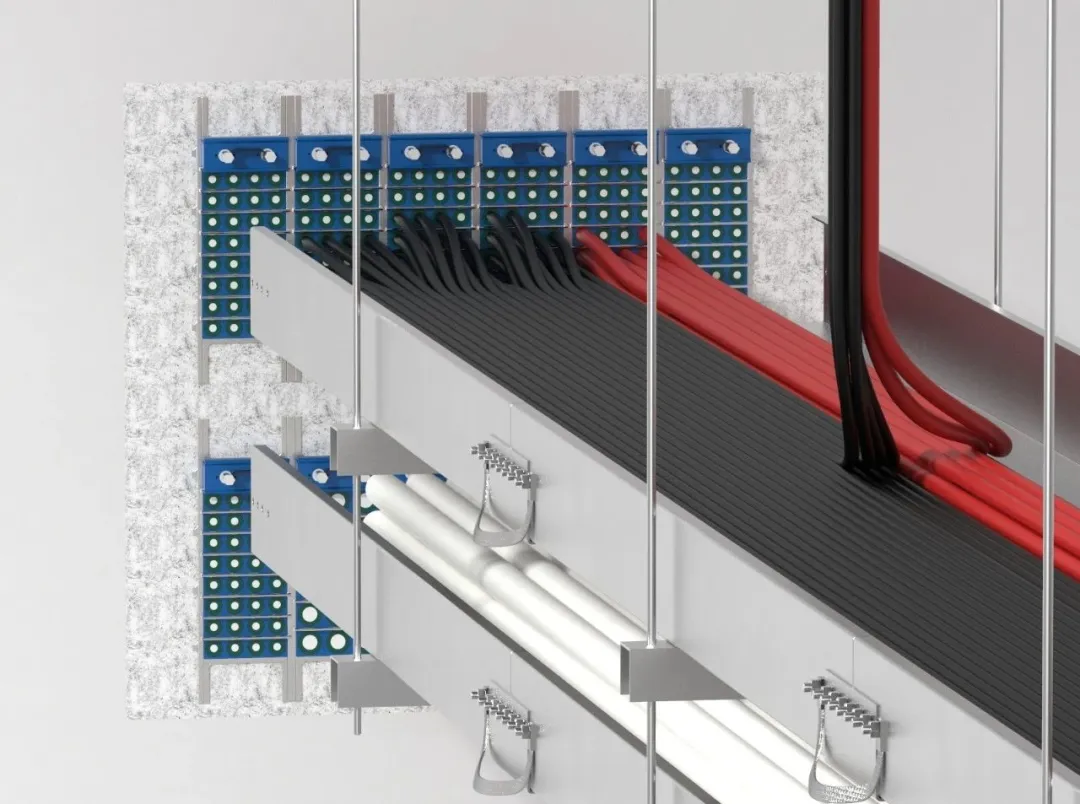

TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

Detailed explanation of the application, advantages and product characteristics of TST SEAL sealing modules

In modern industry, sealing modules are key components to ensure the safe operation of equipment, prevent leakage and improve efficiency. They are widely used in many fields such as petroleum, chemical industry, shipbuilding, and electricity. With the development of technology, sealing modules not only need to meet the stringent requirements under high pressure, high temperature or corrosive environment, but also need to have the characteristics of high efficiency, environmental protection and long life. This article will introduce the application scenarios, product advantages, core characteristics and TST SEAL sealing module solutions of sealing modules in detail.

- What is a sealing module?

A sealing module is an integrated sealing system, usually composed of a flange body, a gasket, a bolt and possible auxiliary sealing structures, which is used to ensure that the connection between pipelines, valves, pumps or other equipment has good sealing performance. It achieves effective isolation of gas, liquid and even solid particles through the optimization of material selection, structural design and installation process.

- Industry application scenarios of TST SEAL sealing modules

- Oil and gas industry

In the process of oil and gas extraction, transportation and refining, sealing modules are widely used in high-pressure pipelines, wellhead devices, separators and compressor interfaces. Since the medium is often corrosive and the operating pressure is high (up to 100MPa or more), the pressure resistance and chemical corrosion resistance of the sealing system are extremely high.

- Chemical and pharmaceutical industries

Chemical production involves a large number of strong acids, strong alkalis and toxic and hazardous substances. The sealing module must have excellent chemical stability to prevent leakage from causing environmental pollution or safety accidents. At the same time, in the pharmaceutical industry with high cleanliness requirements, the sealing module must also meet GMP standards.

- Ship and marine engineering

Ship power systems, hydraulic transmission devices and liquefied natural gas (LNG) storage tanks all rely on high-quality sealing modules to cope with challenges such as deep sea pressure, low temperature (-162℃ LNG) and salt spray corrosion.

- Nuclear power and energy industry

The cooling system and turbine connection of nuclear power plants have extremely high requirements for the reliability of the sealing module. An all-metal sealing structure is required to ensure zero leakage and meet the ASME B16.5 Class 900 grade standard.

- Military and aerospace

Sealing modules used in extreme environments such as rocket fuel pipelines and aircraft hydraulic systems must have comprehensive properties such as lightweight, high and low temperature resistance (-200°C to +300°C) and vibration and shock resistance.

III. Core advantages of TST SEAL sealing modules

- Strong high-pressure tolerance

Advanced sealing modules can withstand pressures up to 100MPa and are suitable for extreme working conditions such as high-pressure gas wells and deep-water drilling platforms.

- Excellent corrosion resistance

Made of high-performance materials such as stainless steel, duplex steel, Hastelloy, etc., it can effectively resist corrosion from corrosive media such as hydrogen sulfide and chloride ions.

- Stable and reliable sealing effect

The precision-machined flange surface is combined with gaskets of special structure (such as corrugated gaskets, octagonal gaskets, and flexible graphite winding gaskets) to ensure long-term use without micro-leakage.

- Convenient installation and maintenance

The modular design supports quick replacement and installation. Some self-tightening sealing modules do not need to frequently adjust the bolt preload, greatly reducing operation and maintenance costs.

- Environmental protection and energy saving

The use of environmentally friendly materials such as new asbestos-free gaskets and low-VOC coatings complies with international environmental regulations (such as REACH, IMO 2020) and promotes green manufacturing.

- Analysis of product characteristics of TST SEAL sealing modules

- Material diversity

Depending on the different use environments, the sealing modules can be made of carbon steel, stainless steel (such as 304/316L), alloy steel (such as 2.25Cr-1Mo) or special alloys (such as Inconel 625, Hastelloy C-276) and other materials.

- Advanced structural design

Including but not limited to:

Concave and convex flange: Enhanced sealing contact area;

Trapezoidal groove flange: Suitable for metal octagonal gaskets, suitable for high-pressure occasions;

Self-tightening flange: Use internal pressure to automatically enhance the sealing effect;

Magnetic sealing module: Easy to quickly replace and improve maintenance efficiency.

- Intelligent monitoring function

Some high-end sealing modules integrate optical fiber sensors to monitor the sealing status in real time, warn of potential leakage risks in advance, and improve system safety.

- Digital management support

Combining digital twin technology and intelligent selection system, enterprises can automatically recommend the best sealing solution according to specific working parameters to improve procurement and maintenance efficiency.

- Advantages of TST SEAL’s sealing module products

As a leading domestic sealing solution provider, TST SEAL focuses on the research, development, production and sales of various high-performance sealing modules, and its products are widely used in many major projects around the world.

- Leading technology

The self-developed self-tightening sealing module has obtained a number of national patents and can automatically enhance the sealing effect under high pressure.

Advanced CNC machining center ensures that the flange surface accuracy reaches Ra ≤1.6 μm.

- Excellent quality

All products are certified by ISO 9001 quality system;

Many products meet domestic and international standards such as API, ASME, GB/T;

Provide customized services to meet customers’ personalized needs.

- Rich application cases

TST SEAL has provided supporting sealing modules for large enterprises such as the Three Gorges Hydropower Station, State Grid, and China Railway Construction;

There are successful application cases in cruise transport ships, deep-sea drilling platforms, hydropower, wind power, and nuclear power projects.

- Perfect after-sales service system

Service centers are set up in many places to provide 7×24-hour technical support;

Provide one-stop services such as regular inspections, fault diagnosis, and spare parts supply;

Support remote online monitoring and data analysis.

- Frequently Asked Questions (FAQ) about Sealing Modules

Q1: What is a sealing module?

A: A sealing module is an integrated sealing component used for the connection parts of industrial equipment. It is usually composed of flanges, gaskets, bolts, etc., designed to prevent medium leakage and ensure the safe operation of the system.

Q2: What industries are the sealing modules suitable for?

A: It is widely used in the fields of petroleum, natural gas, chemical industry, shipbuilding, electric power, military industry, aerospace, etc., especially in high-pressure, high-temperature, and highly corrosive working environments.

Q3: How to choose a suitable sealing module?

A: It should be considered comprehensively based on factors such as working pressure, temperature, medium type, and connection method. It is recommended to consult professional suppliers for selection and matching.

Q4: Does the sealing module require regular maintenance?

A: Yes, especially for traditional flange sealing structures, it is necessary to regularly check the bolt preload and gasket aging. Some intelligent sealing modules support online monitoring to reduce the frequency of manual inspections.

Q5: What are the advantages of the sealing modules provided by your company?

A: TST SEAL’s sealing modules have the characteristics of self-tightening structure, high pressure resistance, corrosion resistance, and environmentally friendly materials. They have passed many international certifications and serve many key engineering projects.

Q6: Can the sealing module be customized?

A: Yes. We provide a full range of customized services from materials, sizes to structures to meet the special needs of different customers.

VII. Conclusion

With the continuous improvement of industrial automation and intelligence, sealing modules are moving towards higher performance, more environmentally friendly, and smarter directions. Whether in traditional industries or emerging energy fields, sealing modules play an indispensable role. With strong technical R&D capabilities, strict quality control system and perfect after-sales service network, our company is committed to providing customers with the most reliable sealing solutions.

If you are looking for high-quality, high-performance sealing modules, please contact TST SEAL. We will provide you with professional selection suggestions and technical support, and you can also get free samples!

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome (Email:alixich@tstcables.com)