TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

Under the new SHT3006-2024 regulations, TST seal penetration seal modules build a solid safety barrier for petrochemical control rooms

Blood lessons are rewriting safety standards

In the 2019 Xiangshui explosion accident, the control room did not meet the explosion-proof standards, resulting in the death of all 78 operators – this exposed the fatal flaws of the old version of the specification (2012 version): the explosion-proof design was only a “suggestive clause” and the fireproof seal had a fire resistance limit of only 1.5 hours.

Data from the Ministry of Emergency Management in 2023 showed that 62% of control room accidents were caused by penetration seal failure, becoming the second largest risk source after electrical fires.

With the official implementation of the “Petrochemical Control Room Design Specification” (SHT3006-2024), the petrochemical industry is reconstructing the safety line with quantitative parameters. TST seal cable and pipeline penetration seal modules, with full-dimensional performance that is deeply in line with the specifications, provide the industry with a full life cycle safety solution.

01 Fire and explosion prevention: Building a solid safety bottom line

Article 6.5.2 of the new regulations clearly requires that the penetration parts of the explosion-proof wall maintain structural integrity, and Article 8.3.3 requires fire blocking for more than 2 hours. The response strategy of the TST seal fire penetration device directly hits the pain point:

Dual system fire protection certification

Passed the GB23864 standard 2h/3h fire protection certification + CUTR 2h fire protection certification, and met the highest fire risk level requirements of EN45545-2 HL3, providing “double insurance” for the explosion-proof wall.

Hard-core explosion resistance

Can block 1.8MPa explosion impact (far exceeding the conventional 0.1MPa requirement), meet the IEC 60079 Ex EПC Gb explosion-proof level, and perfectly respond to the stringent requirements of the specification for explosion-proof sealing.

Engineering value: In key areas such as the control room outer wall and explosion-proof partition wall, the TST seal modular sealing system can simultaneously meet the fire and explosion requirements, avoiding the risk of multiple blocking of traditional solutions.

02 Ultimate sealing: resisting erosion and penetration

Clause 8.2.4 of the specification requires that the penetration part reach the IP66 protection level, and Appendix C emphasizes special protection in corrosive environments. The innovative design of the TST seal penetration sealing system achieves triple defense:

Dynamic pressure sealing

Supports 0.3~0.5MPa watertight/airtight pressure (covering common pressure scenarios in petrochemicals), and still maintains IP68 protection level after vibration and impact (IEC 61373/GB/T21563 test).

Double anti-corrosion architecture

316L stainless steel shell: molybdenum content ≥2%, salt spray test >1000 hours without rust, chloride ion corrosion resistance is 3 times that of carbon steel

EPDM seal body: passed UL aging certification, performance degradation <15% after aging for 1000 hours at 85℃/85% humidity

Wide temperature range adaptability

Under extreme temperature fluctuations of -52℃~90℃ (such as severe cold in the north or high temperature areas in refineries), the sealing structure remains stable.

Scenario adaptation: In high-risk corrosion scenarios such as coastal high-salt fog factories and acidic and alkaline gas environments, the golden material combination of TST seal can extend the life of the equipment by more than 30%.

03 Engineering friendliness: a tool for reducing costs and increasing efficiency

In response to the requirement of reserving expansion space in specification 8.3.5, MCT gave a subversive answer:

30-year maintenance-free design: The ultra-durable combination of EPDM rubber and 316L stainless steel greatly reduces the frequency of maintenance

International authoritative endorsement: CCS, RS and other classification society certifications have been obtained, and DNV, BV, ABS, LR and other certificates have been obtained in the certification stage, further verifying that TST seal sealing module products have their excellent performance. TST seal protects industrial safety, defines excellent quality, and wins market and user satisfaction with product strength.

Comparison table of specification clauses and TST seal penetration sealing technology

Specification clauses | Core requirements | TST seal solution | Certification basis |

6.5.2 | Explosion-proof structural integrity | 1.8MPa explosion-proof impact | IEC 60079 |

8.3.3 | Fire protection ≥ 2h | GB23864 2h/3h certification | CUTR certificate |

8.2.4 | IP66 protection | IP68 sealing after vibration | IEC 61373 |

Appendix C | Corrosion protection | 316L+EPDM weather-resistant system | 1000h salt spray test |

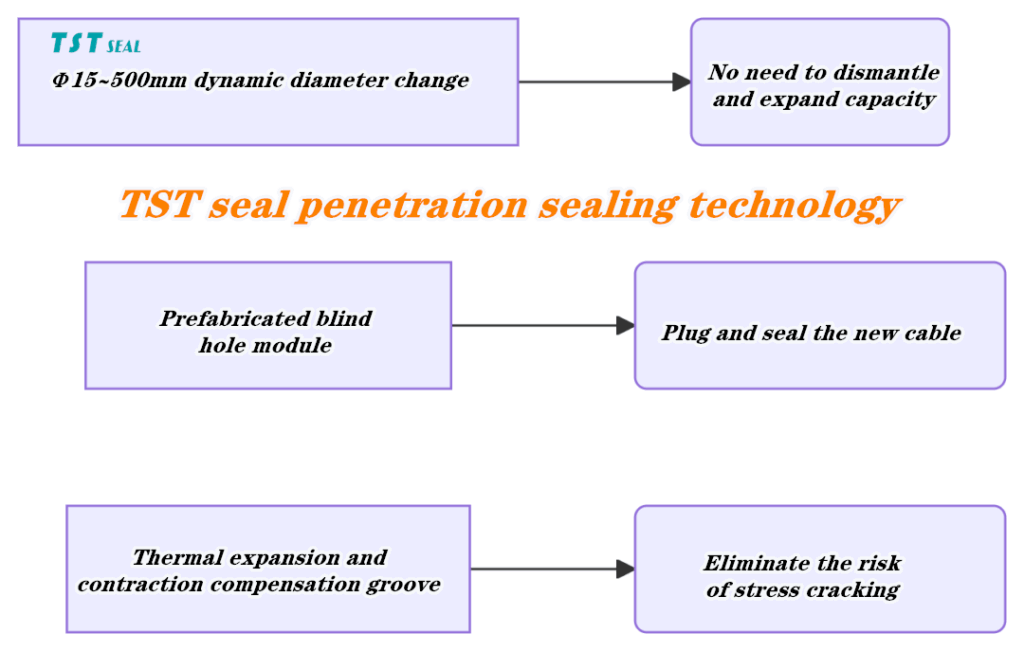

8.3.5 | Reserved space for expansion | Blind hole module+dynamic variable diameter | Support Φ15~500mm coverage |

The upgrade of SHT3006-2024 is not only an iteration of specifications, but also an evolution of petrochemical safety philosophy. The TST seal fireproof plugging module has passed various data tests, based on measured data, meets IP68 dynamic sealing, has dual certifications for fire and explosion resistance, and meets 30 years of maintenance-free and other indicators, transforming regulatory clauses into quantifiable safety barriers. In the control room, the “nerve center” of the petrochemical plant, each penetration and sealing point is a key link in the safety line of defense – choosing a sealing solution that can withstand the test of the entire life cycle is the most solemn commitment to safe production.

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome (Email:alixich@tstcables.com)