TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

- MCT Transit Sealing System (11)

- rectangular seal (41)

- sealing modules (49)

- sealing solution (20)

- Tensioning Block (1)

How does TST seal's modular MCT system build a maritime "firewall"

Due to its absolute emphasis on the safety of assets and lives in the global shipping industry, the International Maritime Organization (IMO) regulates the fire resistance of marine materials with strict standards. TST seal strictly follows the FPT rules and uses innovative technology to develop modular cable and pipe penetration sealing systems (MCT) fireproof plugging materials that can cope with complex maritime environments to the extreme. Under the witness of the international classification society certification system, it uses innovative design, precise deployment, and pre-processing of ship fire risks to provide global maritime with safe, controllable, efficient, and cost-controlled lean solutions.

I will combine the FPT rules and the experimental measured data of the Far East Fire Test Center of the Shanghai Standards Institute to deeply analyze the technical core and show you how TST seal builds the “first firewall” for ships through three core values——

The lethality of ship fires often stems from the rapid spread of fire between cabins, and the cable and pipe penetrations are the key paths for the spread of fire, smoke, and toxic gases. Part 3 of the International Maritime Organization (IMO) FTP rules specifies the fire resistance requirements for “A”, “B” and “F” class divisions in ship structures:

Fire performance | Class A separation | Class B division | F-class partition |

Material and structure | The main body is made of steel or equivalent non-combustible materials, and the joints must be fireproof and sealed | Use approved non-combustible materials, allow | It is required to pass a 30-minute fire resistance test, focusing on the ability to resist fire flame penetration. |

Thermal insulation performance | The average temperature rise of the back-fire surface does not exceed 139°C | Surface decoration layer is low flame spread material | |

Integrity | The maximum temperature rise of a single point does not exceed 180°C | The average temperature rise of the back fire surface does not exceed | |

Application area | It is divided into four levels: | 139℃, and the maximum temperature rise of a single point does not exceed | For special cabins, such as kitchen exhaust duct |

The safety and controllability of the TST seal modular sealing system (MCT) stems from its breakthrough in fire resistance.

- A-60 certified fire test performance

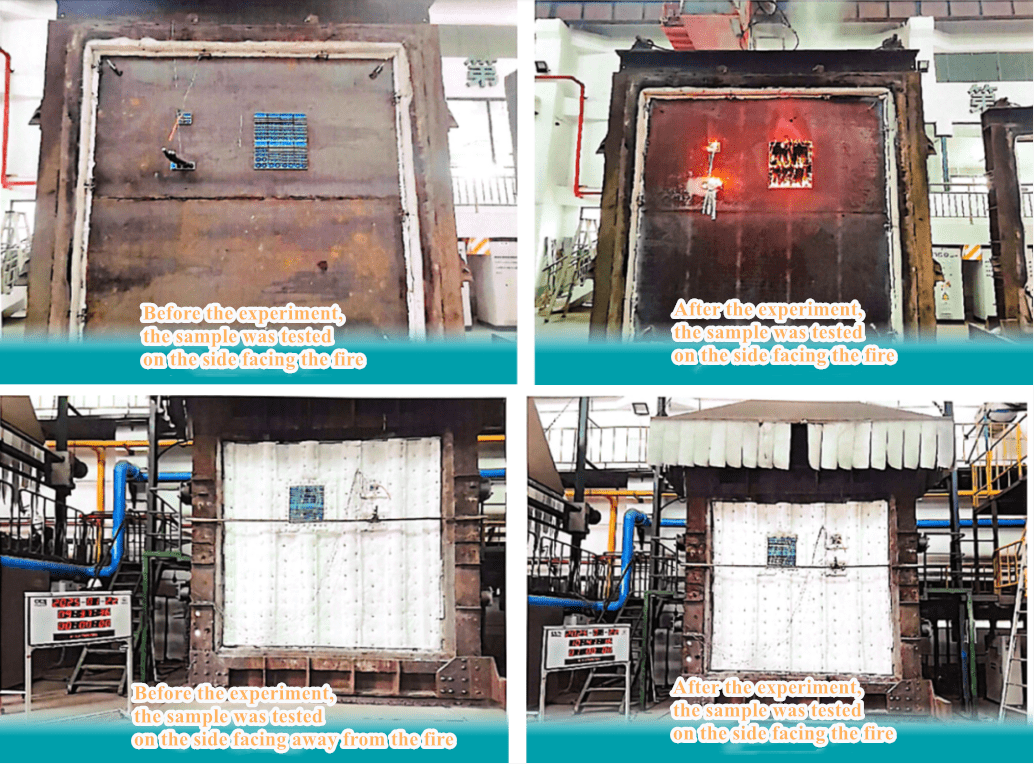

TST seal strictly follows the core standard of Part 3 of the International Maritime Organization (IMO) FTPC “A-class fire resistance division test”. Its independently developed ship bulkhead cable penetration device has been authoritatively tested by the Far East Fire Test Center of the Shanghai Standards Institute and successfully passed the standard fire resistance test for ship A-class bulkhead and deck cable penetration devices.

[Highlights of the test] Authority of certification:

The whole process passed the A-60 level certification of the Far East Fire Test Center, and the technical indicators fully met the standards; Triple performance guarantee:

Fire resistance integrity, thermal insulation, and air tightness all achieved 100% compliance, and the back-fire surface structure remained intact under extremely high temperatures; Temperature control breakthrough:

The highest temperature rise of the back-fire surface in the experiment was only 154°C, significantly lower than the international limit standard of 180°C;

Safety redundant design:

There was no smoldering phenomenon in the cotton pad ignition test, no leakage in the air tightness throughout the process, and the risk of flame penetration was completely zero.

[Technical value]

This test verified the all-round breakthrough of the TST sealMCT system in material flame retardancy, structural stability and dynamic protection capabilities, and set a new quantitative benchmark for fire safety in key parts of ships.

▲Experimental site of Far East Fire Test Center of Shanghai Standards Research Institute

- Four-dimensional security protection design

Four-dimensional security protection design –

TST seal modular cable and pipe penetration sealing system has built a four-dimensional protection system through the deep integration of material science and structural engineering:

High temperature resistant ceramic fiber material

Instantly absorbs high heat energy and blocks heat conduction;

EPDM rubber:

Excellent aging and weather resistance, excellent heat resistance after adding special process, and wide operating temperature range;

316L stainless steel:

Stable performance and excellent performance under high temperature environment;

Modular redundant structure:

Adopting segmented sealing design, single point failure does not affect the overall performance.

TST seal has not only passed the rigorous test of the entire series of IMO FTP Code, but also has become a professional “ship firewall” domestic alternative with its four-dimensional security protection design.

The “peelable variable diameter” modular structure of TST seal systematically improves the fire protection performance through the triple mechanisms of dynamic adaptability, sealing continuity and maintenance efficiency. The essence is to upgrade the penetration seal from “static filling” to “dynamic defense system” – through the triple technical logic of structural adaptation, material self-repair, and maintenance self-verification, it solves the core pain points of traditional solutions in adaptability, durability, and maintainability. There is no need to destroy fire separation and replace cables without damage, so that the fire protection performance of the ship penetration part is improved to a new dimension of full-cycle, full-condition, and full-scene reliability, providing a disruptive solution of “one-time installation, lifelong worry-free” for maritime safety.

- Optimization of the whole life cycle maintenance – Traditional sealing materials need to be re-inspected for fire protection performance every 2 years, while the TST seal system adopts a “peelable variable diameter” modular structure to support the rapid replacement of a single cavity without overall dismantling, reducing maintenance costs by more than 60%.

- Time cost compression

Time cost compression – In the ship maintenance scenario, the modular replacement mode can shorten the single maintenance time from 8 hours to 1.5 hours, greatly compressing the time cost and significantly reducing the operating losses caused by the shipowner’s maintenance downtime.

- Risk cost transfer

Risk-cost transfer – Changes in the ship’s classification society or ship grade will affect the insured unit’s quantitative assessment of the ship’s fire risk. The A-60 certified fire protection performance transfers the risk cost for the shipowner.

In the maritime fire safety track, TST seal is well aware that every penetration and sealing point is the “throat” of ship safety and a reverence and protection for life. TST seal strictly follows the self-requirement of international standards, transforms the three core elements of safety, efficiency and cost into quantifiable and verifiable technical indicators, and provides global shipowners, shipyards and design institutes with penetration and sealing solutions for key parts such as cabins, decks, ceilings, linings, doors and windows, and pipe penetrations. We sincerely invite global shipowners, shipyards and maritime colleagues to discuss and exchange ideas, promote the iterative upgrade of maritime fireproof sealing solutions through technical mutual learning, and work together to push the industry safety standards to a new height!

Safety is no small matter, and prevention is before it “ignites” – let TST seal be the guardian of your ship’s fire safety.