TST Seal :

- Fireproof

- Cable fixinAg

- Watertight

- Airtight

- Dustproof

- Noise reduction

- Vibration reduction

- Pressure resistance

- Corrosion resistance

- EMI/EMP

- Pest & rodent resistance

Related Articles

- circular seal (7)

- flange sealing (1)

- industrial sealing (2)

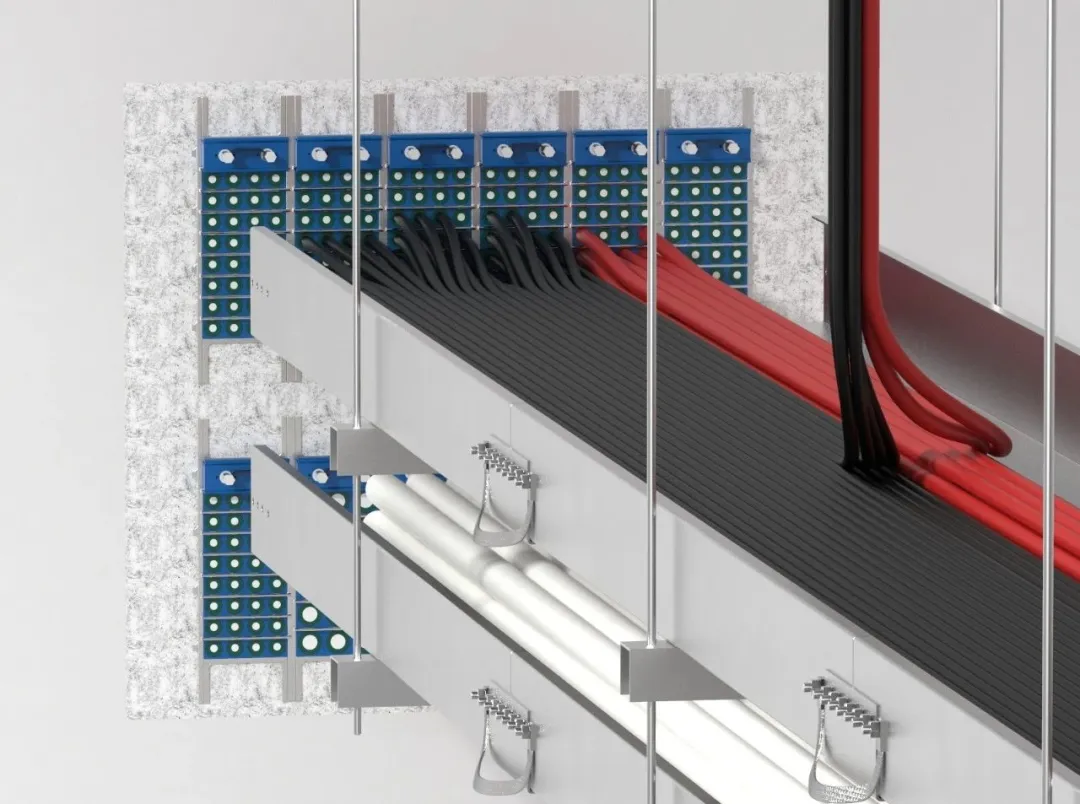

- MCT Transit Sealing System (12)

- rectangular seal (41)

- sealing modules (53)

- sealing solution (22)

- Tensioning Block (1)

5 Common Cable Seal Module Procurement and Selection Mistakes That Buyers Often Overlook

In critical fields such as shipbuilding, offshore engineering, rail transit, and new energy power plants, cable seal modules are the “last line of defense” for ensuring system safety. However, many engineers and procurement personnel often fall into seemingly reasonable but actually dangerous cognitive biases during selection, which can lead to minor problems like water or air leaks, or more serious issues such as fires, equipment downtime, or even safety accidents. Below are five common selection mistakes, and TST SEAL will help you avoid these five “invisible traps” that procurement personnel most easily overlook.

Mistake 1: “All rubber is pretty much the same, cheaper is better” – Ignoring material compatibility

Typical manifestation:

“Aren’t EPDM, silicone, and fluororubber all just rubber? The price difference is threefold, why waste money?”

The truth:

Different rubbers have vastly different resistance to media, temperature, and oil contamination:

EPDM: Resistant to water and ozone, but swells and fails when exposed to mineral oil and fuel – absolutely unsuitable for engine rooms or hydraulic stations;

Silicone: Soft and resistant to high and low temperatures (-60℃~200℃), but has low tear strength and is easily scratched by armored cables;

Fluororubber (FKM): Oil and high-temperature resistant, but becomes brittle at low temperatures, unsuitable for Arctic or cold storage environments.

✅ Correct approach:

Clearly define the media in contact with the seal (seawater, lubricating oil, chemicals, etc.), and require the supplier to provide a material compatibility table or third-party test report.

📌 Case study: An LNG ship used ordinary EPDM sealing modules in the fuel pump area. After 3 months, the rubber swelled and detached, leading to oil leakage and fire in the engine room.

Mistake 2: “The hole size is close enough” – Ignoring cable tolerance and dynamic deformation

Typical manifestation:

“The cable outer diameter is 40mm, so a Φ40 hole is perfect!”

The truth:

The actual outer diameter of the cable has a tolerance of ±1~2mm;

Ships/wind turbine towers experience structural deformation or vibration displacement during operation;

If the sealing hole and the cable are a “perfect fit,” it will actually prevent effective compression sealing and may even damage the cable sheath due to friction. ✅ Correct Approach:

Choose TST SEAL peelable or multi-path modules with an aperture slightly smaller than the cable outer diameter (usually 1-3mm smaller), relying on rubber elasticity for interference fit sealing; or use a dynamic compensation design that allows for ±5mm installation error.

Misconception 3: “Fire protection relies on the rubber itself” – neglecting system-level certification

Typical manifestation:

“This rubber is flame-retardant, so it must be fireproof!”

The truth:

A single piece of rubber cannot pass the A-60 fire test! Fire protection performance depends on the entire penetration system:

The metal frame must be high-temperature resistant and not deform;

Fire-resistant sealant must be used between the module and the wall;

The overall structure must pass standards such as IMO FTP Code and EN 1366-3.

⚠️ Many products on the market only claim to be “flame-retardant” but lack A-60 certification from classification societies, and fail quickly in actual fires.

✅ Correct Approach:

Require suppliers to provide fire test reports and certificates for the entire system (such as DNV A-60, CCS H-120), not just material data sheets.

Misconception 4: “Install it once and forget about it” – ignoring future expansion needs

Typical manifestation:

“We need to run 20 wires now, just drill fixed holes.”

The truth:

Projects often require adding sensors, communication lines, or backup circuits later. Traditional fixed-hole modules, once installed, cannot be expanded, leading to:

Damage to the original seal;

Drilling new holes, weakening structural strength;

Downtime for several days, resulting in huge losses.

✅ Correct Approach:

Prioritize TST SEAL peelable rubber blocks or modular quick-connect systems that support single-sided expansion without disassembly or power interruption.

📌 Case Study: A certain offshore wind power substation was forced to shut down for modification due to inability to expand, resulting in a single loss exceeding €500,000.

Misconception 5: “Domestic products = low-end, imported products = reliable” – blindly favoring foreign products or driving down prices

Typical manifestation:

Either only recognizing European and American brands, leading to budget overruns;

Or blindly driving down prices, choosing products from small manufacturers without certification. The Truth:

Leading Chinese companies (such as TST CABLE/TST SEAL) have obtained a full range of certifications from DNV, BV, ABS, CCS, etc., and their performance is comparable to international standards;

Meanwhile, some “branded imported” products are actually domestically manufactured under contract, resulting in inflated prices;

Low-priced, unbranded products often use recycled rubber and carbon steel frames, failing salt spray tests in less than 100 hours due to corrosion.

✅ Correct Approach:

Base your decision on certifications and actual test results, focusing on performance rather than origin. Require sample testing, factory audits, and verification of similar project case studies.

Sealing is no small matter; professional selection is crucial.

Although the TST SEAL cable conduit sealing module is small, it is the most vulnerable and critical link in the safety chain. Avoiding the above misconceptions is not “overly cautious,” but rather a responsible approach to life, assets, and projects.

Remember: Every penny saved on cable gland sealing can potentially cost ten times more in the future.

Choosing the right module means choosing peace of mind.

Free Sample | Customization Supported | Global Sales | Factory Direct Sales | Agents Welcome |Ships within 24 hours (Email:alixich@tstcables.com)

TST SEAL has obtained certifications from DNV, RS, ABS, BV, RINA, CCS, CRCC, CCC, IOS, EN, ROHS & REACH, etc.